Assembly of a fire-rated loft ladder

The Supreme F30 with wooden hatch box is a great choice for commercial and industrial use where fire protection is required. The heavy duty loft ladder offers both strength and durability, yet remains very easy to operate (just 3 kg operating load). In addition, the wooden hatch box offers 30 minutes of fire resistance (from below), good thermal insulation and an airtight seal.

How its made…

Each Supreme F30 is hand-assembled, before being fitted to a test rig for final set-up and inspection. This blog provides an insightful overview of the assembly process, highlighting the careful attention to detail that goes into every single one of the products we offer.

Fire rated hatch box construction…

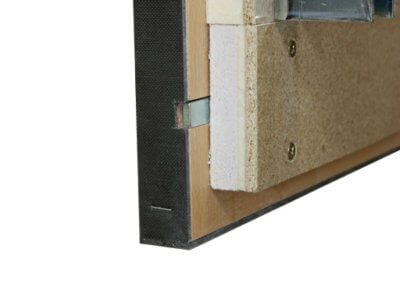

Each Supreme F30 with wooden hatch box is made-to-order from fire resistant chipboard B1. This is because each hatch box is made to fit the exact dimensions of the project. As a result, the loft ladder achieves a perfect fit when it is installed. In turn, this saves time on-site and ensures a high-quality finish.

As can be seen in the image above, the corners are fixed together with steel brackets. Therefore, this gives the frame the strength and rigidity it needs for use in commercial and industrial buildings. Also, a thick steel bracket is used to reinforce the section that holds the ladder to the hatch box frame. The end result is a loft ladder that is able to support a load of 200 kg per tread.

The hatch / trapdoor is a sandwich construction with flame retardant melamine coated chipboard and insulating panel. It also features Promaseal-PL around the perimeter that expands when heated to create a seal against the spread of fire and smoke. The hatch is secured via a 2-point latching system.

Concertina ladder assembly…

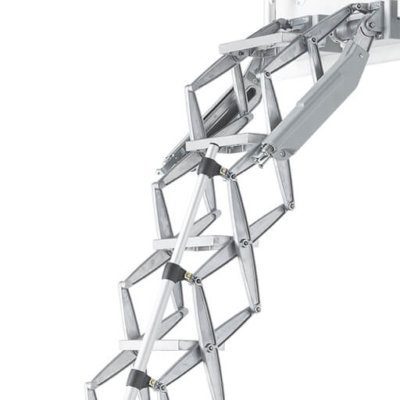

The next step is to assemble the concertina ladder. Like the hatch box, each one is prepared to order. The side arms are fitted together in a jig, then each tread is bolted in place at precisely the right angle (as shown in this photo). As a result, the treads are perfectly flat when the Supreme F30 loft ladder is extended to the floor.

The ladder is made of cast aluminium components. This gives them high strength and rigidity. Also, it helps keep the weight to a minimum, such that it is as easy to operate as possible.

In addition, the concertina ladders are fitted with non-slip protective feet. These help prevent damage to floors when the ladder is in use and under heavy loads.

Final assembly and testing…

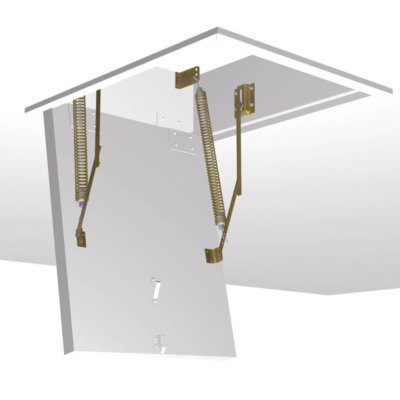

Finally, the concertina ladder can be fitted to the hatch box. As can be seen from this photo, the Supreme F30 loft ladder uses gas struts to counter-balance its weight. As a result, the ladder can be opened and closed with ease. Also, the gas struts prevent the ladder from falling down under its own weight, therefore improving safety.

Each Supreme F30 is then put onto a test rig. A few finishing touches are applied, it is inspected and tested. Final adjustments are made to the loft ladder, if necessary, and it is sent off for packaging and dispatch.

Learn more about our range of loft ladders…

…or contact us to discuss your requirements.

We hope you found this helpful!

If so, please feel free to share this article with family, friends and colleagues so that they can also benefit. Also, why not follow-us on social media for further tips, ideas and the latest product news…