Premier Loft Ladders were contacted by a specialist food processing plant to replace a damaged retractable roof access ladder. As this presented the only means of access for maintenance of roof top equipment, it was important that the replacement access ladder was strong, durable and easy to operate. The Supreme with flat roof access hatch provided the perfect solution.

The challenge…

For many years, the only means of access to provide essential regular maintenance of roof top equipment at a specialist food processing facility was via a retractable roof access ladder. Directly above the ladder was a small section of vertical ladder that led to an old roof hatch. Although the ladder was heavy-duty rated, it was severely damaged by a side-impact. As a result, it was unsafe to use.

Premier Loft Ladders carried out a site survey to assess the damage and see if it could be repaired, or if a replacement was needed. Due to the extent of the damage, a replacement ladder was the only option. Furthermore, it was identified that the ladder was integrated within the roof hatch. The roof hatch was particularly old and was also in need of replacement.

Above: Damaged retractable roof access ladder.

The solution…

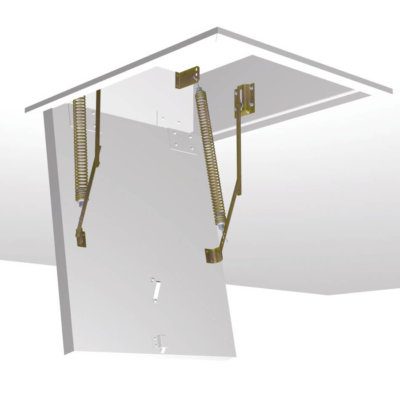

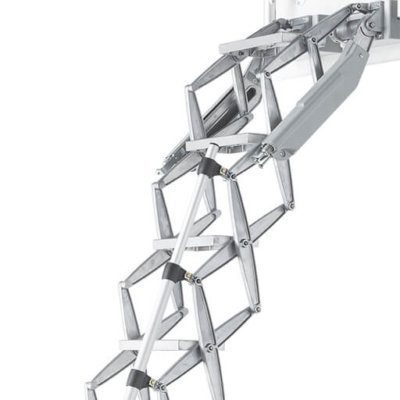

The requirement for regular access to the roof and heavy duty performance meant that the Supreme retractable access ladder was the best solution. In addition, it could reach the 3.75m high ceiling with ease, and could be made to fit the exact measurements of the existing roof aperture. Also, the Supreme is available complete with an insulated and weatherproof flat roof access hatch. As such, it made removal of the old retractable roof access ladder hatch and replacement with the Supreme much easier.

Above: Retractable roof access ladder and hatch. Providing access for maintenance of roof top equipment.

The Supreme retractable flat roof access ladder benefits from a high strength aluminium concertina ladder. Also, it is expertly engineered to make it as easy as possible to open and close (requiring less than 3kg of operating force). This is particularly important for such a high ceiling and ensuring the health and safety of employees using the ladder. Furthermore, the Supreme features large treads (measuring 380mm wide by 140mm deep in this instance), along with a telescopic handrail and non-slip protective feet as standard.

For this project, the ladder itself was fitted within a deep hatch box to suit the ceiling/roof thickness, and topped with a zinc clad roof hatch. The insulated upper and lower hatch doors combine to offer a very high level of insulation and an airtight seal.

Installation of the retractable roof access ladder and hatch…

The client needed the help of a specialist to install the Supreme, and asked Premier Loft Ladders for recommendations. Due to their experience with our products and the type of project, we suggested Mantech Safety Systems, who specialise in fall protection equipment and safe access solutions. Mantech organised all of the on-site logistics, removing the old damaged ladder, and replacing it with the made-to-measure Supreme. They then added insulation to the outside of the hatch box (above the roof deck) and applied the waterproof membrane.

Above: Weatherproof roof access hatch, fitted by Mantech Safety Systems

The results…

The damaged retractable roof access ladder presented a significant safety hazard for staff at the food processing plant. It also prevented access to the roof top for important maintenance of the equipment. However, the new ladder now provides safe access and is easier to operate than the old one that it replaces. Furthermore, the integrated roof hatch provides better insulation and an airtight seal, which will help to reduce cold draughts and keep in the warmth during the winter months. Also, the weather resistant upper hatch, combined with the new water-proof sealing applied around the upstand by Mantech Safety Systems, will ensure many years of service and piece-of-mind for the factory owners and its maintenance team.